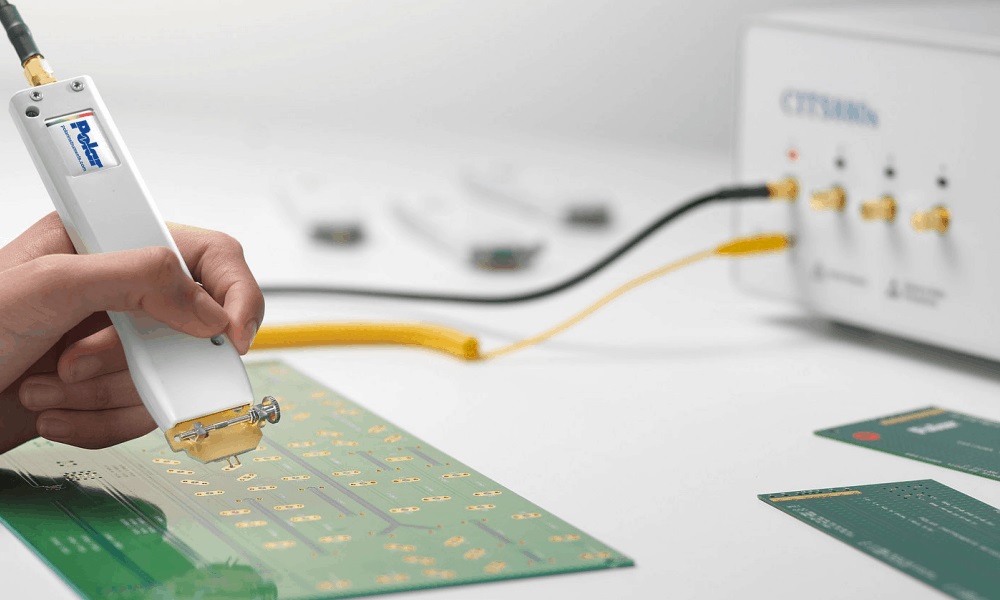

Are you ready to witness the power of prototype PCBs?

These game-changing circuit boards are revolutionizing industries across the globe.

With their ability to streamline product development processes, enhance efficiency and cost-effectiveness, and accelerate time to market, prototype PCBs are driving innovation and competitiveness like never before.

In fact, studies have shown that companies utilizing prototype China PCB have experienced a 30% increase in productivity.

Join the movement and discover how these cutting-edge technologies can propel your industry forward.

Streamlining Product Development Processes

Streamline your product development processes by utilizing prototype PCBs.

Prototype PCBs are revolutionizing industries by improving design iteration, enhancing collaboration, and communication.

With prototype PCBs, you can quickly iterate on your designs, allowing for faster development and testing cycles. This means you can identify and resolve design flaws and make necessary adjustments more efficiently.

Additionally, prototype PCBs facilitate collaboration among team members by providing a tangible and visual representation of the product. This enables better communication and understanding between designers, engineers, and stakeholders.

By using prototype PCBs, you can create a more inclusive and collaborative environment that fosters belonging and promotes innovation.

Enhancing Efficiency and Cost-effectiveness

Improve your operational efficiency and reduce costs with the utilization of prototype PCBs. These advanced circuit boards offer numerous benefits that can help your business thrive in today’s competitive landscape.

Prototype PCBs enable you to reduce waste by allowing for more accurate testing and validation of your product designs before full-scale production. By identifying and rectifying any potential issues early on, you can avoid costly mistakes and rework.

Additionally, prototype PCBs play a crucial role in optimizing production processes. Their flexibility allows for quick design changes and modifications, ensuring that your manufacturing operations are efficient and cost-effective.

With prototype PCBs, you can streamline your product development cycle, minimize waste, and maximize productivity, ultimately driving your business towards success.

Accelerating Time to Market

Utilize prototype PCBs to expedite your time to market and gain a competitive edge in your industry.

The ability to quickly develop and test new product designs is crucial in today’s fast-paced market. By using prototype PCBs, you can significantly reduce the time it takes to bring your product to market.

These PCBs allow you to experiment with different design iterations and identify any potential issues before mass production. With the ability to quickly iterate and refine your product, you can ensure that it meets the highest standards of quality.

Additionally, prototype PCBs can help in reducing manufacturing lead times. By having a fully functional prototype, you can streamline the manufacturing process, identify any potential bottlenecks, and optimize production efficiency.

This ultimately results in faster time to market and increased customer satisfaction.

Driving Innovation and Competitiveness

To stay ahead of the competition, businesses can harness the power of prototype PCBs to drive innovation in their industries. Prototype PCBs offer numerous advantages that enable businesses to stay at the forefront of technological advancements and foster economic growth. Here are five ways prototype PCBs can help businesses drive innovation and competitiveness:

- Rapid prototyping: Prototype PCBs allow for quick testing and iteration of new product designs, enabling businesses to bring innovative ideas to market faster.

- Cost-effective development: By using prototype PCBs, businesses can reduce development costs through efficient testing and validation of new concepts, leading to more cost-effective production processes.

- Customization and flexibility: Prototype PCBs offer the ability to create custom designs and tailor products to specific industry needs, promoting innovation and differentiation in the market.

- Collaboration and feedback: Prototype PCBs facilitate collaboration between teams and allow for early feedback from stakeholders, leading to improved product quality and innovation.

- Competitive advantage: By leveraging prototype PCBs, businesses can bring unique and innovative products to market faster, gaining a competitive edge and driving growth in their industries.

Prototype PCBs are a powerful tool for businesses to promote technological advancements, foster economic growth, and stay competitive in today’s fast-paced and ever-evolving industries.

Conclusion

In conclusion, the use of prototype PCBs has revolutionized industries by streamlining product development processes, enhancing efficiency and cost-effectiveness, accelerating time to market, and driving innovation and competitiveness.

These advanced circuit boards act as a catalyst, propelling businesses forward into a realm of endless possibilities. Like the intricate weaving of electrical pathways, prototype PCBs connect ideas and turn them into tangible realities.

With their precise design and technical prowess, they empower industries to thrive in a fast-paced, ever-evolving world.