Inventory is the lifeblood of business. It represents the stock of goods that a company has on hand to sell to customers, and yet it can also be a major drain on resources. Too much inventory can lead to excessive storage costs and missed sales opportunities, while too little inventory can mean lost customers and revenue.

Finding the right balance between these two extremes is essential for success, but it can be difficult to do without the proper tools and techniques. That’s where inventory management comes in.

Inventory management system can be a difficult task for businesses of all sizes. Fortunately, there are inventory management hacks you can do to keep your business lean and efficient.

Whether you’re just starting out or you’ve been in business for years, these tips will help you streamline your operations and improve your bottom line.

1. Know your numbers.

In order to manage your inventory effectively, you need to know how much stock you have and how much space it takes up. You also need to know how much money you’re spending on inventory and what the average sales volume is. This information will help you make informed decisions about what items to stock and how much stock to keep on hand.

2. Keep a close eye on stock levels.

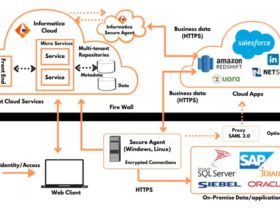

It’s important to keep an eye on your stock levels so that you don’t run out of popular items or fall into a lull in sales. Inventory management system can be utilised to monitor your stock levels and create alerts when items are running low. This will help you stay on top of your inventory and avoid stockouts.

3. Delegate responsibility for inventory management.

In order for inventory management to be successful, everyone in the company needs to be on board. Delegate responsibility for inventory management to specific team members and create clear guidelines for what they need to do. This will help ensure that everyone is aware of their role in maintaining accurate inventory levels.

4. Plan ahead for seasonal fluctuations.

When planning your inventory, take into account seasonal fluctuations in demand. For example, if you sell a lot of snow gear in the winter but very little in the summer, you’ll need to adjust your stock levels accordingly. If you don’t plan for seasonal fluctuations, you may end up with too much or too little stock on hand at the wrong time of year.

5. Use forecasting techniques to predict future demand.

Forecasting techniques can help you predict future demand for your products and adjust your inventory levels accordingly. There are many different forecasting techniques available, so find one that works best for your business and use it to predict demand for upcoming seasons or product launches.

6. Set reorder points based on historical sales data.

When setting reorder points, it’s important to consider both the cost of goods and the lead time required to restock items. By using historical sales data, you can estimate how much stock you’ll need at any given time and set reorder points accordingly. This will help ensure that you never run out of popular items or fall too far behind on restocking new items.

7. Utilize vendor drop shipping.

If possible, utilize vendor drop shipping as part of your inventory management strategy. With this approach, the supplier ships products directly to your customers when they are ordered, which eliminates the need for you to keep any products in stock. This can be a great way to reduce storage costs and minimize excess inventory.

Takeaway

These seven hacks will help you streamline your inventory management process and make sure that you always have the materials you need on hand to run your business successfully.

Implementing just a few of these tips can help you get control over your inventory and stay lean in today’s competitive market. What are you waiting for? Start putting these tips into practice today!